OUR GOAL: Surgically Operate To Deliver the Exact Part and Quantity with Maximum Traceability and Ergonomic Efficiency to Your Line!

At MAAG KIT, we are committed to providing efficient and effective solutions for the aerospace and defense industries. Our precision kitting systems help our clients to optimize their build lines, reduce turnaround time, and increase technician satisfaction.

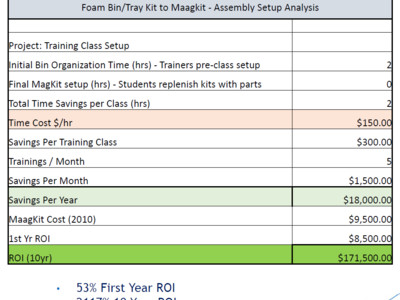

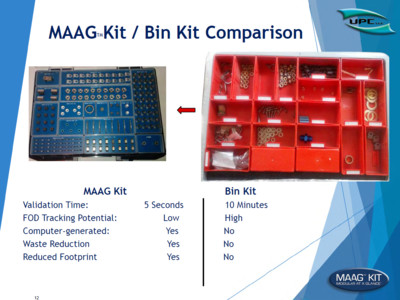

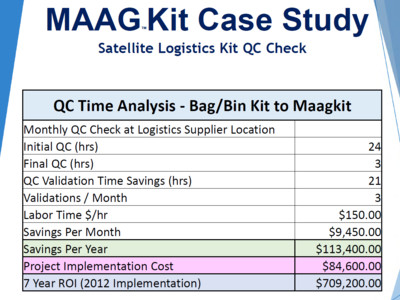

Our case studies demonstrate how MAAG KIT's precision kitting systems have helped our clients to improve material flow, eliminate foreign objects and debris (FOD), and optimize their processes. By organizing small parts efficiently, we have saved our clients time from assembly to refill and reduced validation steps, travel, and counting. Our kitting systems track components as a single entity, making it easy to manage and monitor inventory levels.

All of our precision kitting systems are built to our clients' exact bill of materials and are designed with continuous improvement in mind. Our case studies demonstrate the tangible results that our clients have achieved through the implementation of our kitting systems, including reduced FOD, improved material flow, and increased efficiency.

Take a look at our case studies to see how MAAG KIT has helped other aerospace and defense companies to optimize their processes, reduce turnaround time, and increase technician satisfaction. We are confident that our precision kitting systems can do the same for you.