MAAG KIT's Landing Gear Kit Cases provide a precision kitting solution for mission-critical assembly applications, meeting the high standards of the aerospace and defense industries. Our kit cases are designed with the principles of Poka-Yoke and Kaizen, the continuous improvement methodology developed by Toyota, in mind, to ensure the safe and secure transport and storage of critical hardware and fasteners.

Our landing gear kit cases are engineered with precision and care to meet the demanding requirements of the aerospace industry, utilizing the best practices of Six Sigma. They are made from high-quality, durable materials and feature robust hinges and latches, making them ideal for tough and challenging environments.

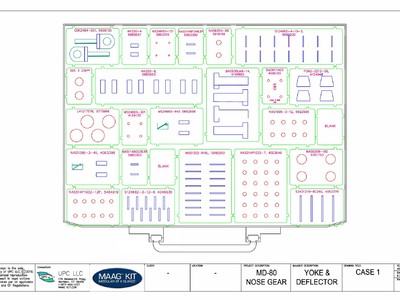

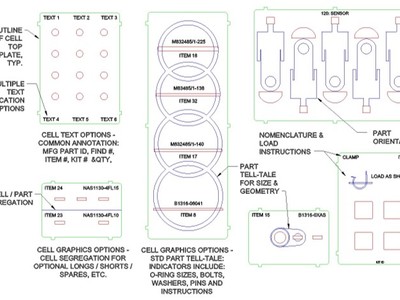

The interior of the landing gear kit cases is fully customizable, with a range of trays, dividers, and inserts available to ensure that all your components are kept organized and secure, promoting the principles of continuous improvement. This not only makes it easy to find what you need quickly, but it also helps to prevent parts from becoming damaged or lost during transit.

At MAAG KIT, we understand the importance of reliable and efficient supply chain management in the aerospace industry and are committed to the principles of continuous improvement. Our landing gear kit cases are designed to provide the ultimate solution for your kitting needs, utilizing the best practices of Kaizen and Six Sigma. Whether you are transporting components for maintenance and repair, or for new assembly projects, our kit cases will ensure that your hardware and fasteners arrive at their destination safe and sound.

In conclusion, if you are looking for a precision kitting system that incorporates the principles of Poka-Yoke, Kaizen, Toyota, Six Sigma, and continuous improvement, MAAG KIT's Landing Gear Kit Cases are the solution you have been searching for. Contact us today to learn more about our range of hardware and fastener kit cases.